Scrubber Design Calculation

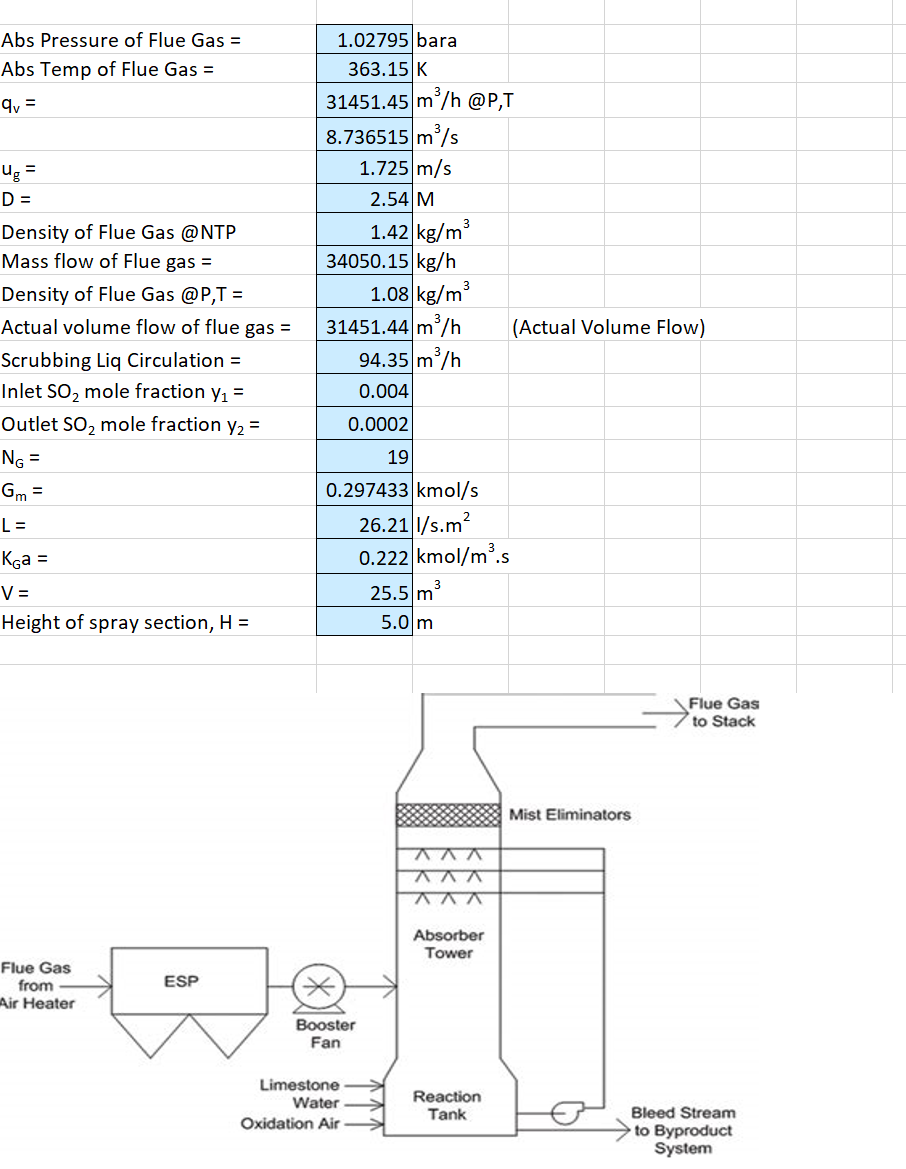

Scrubber design calculation. Average molecular weight of entering gases 400071 Kgkmol from Aspen Gas molar flow rate G in 0568400071 00142 kmols. The humidifying efficiency of the scrubber may be expressed as. In this study the performance and operating experiences of existing utility scrubber systems and the state-of-the- art in design of scrubber components are reviewed.

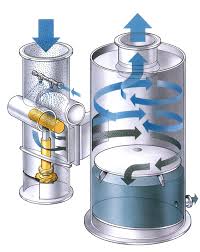

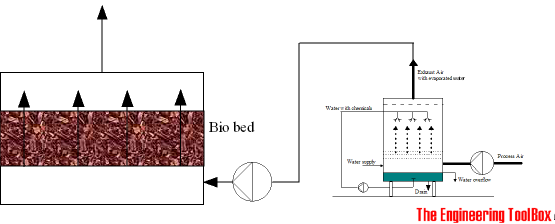

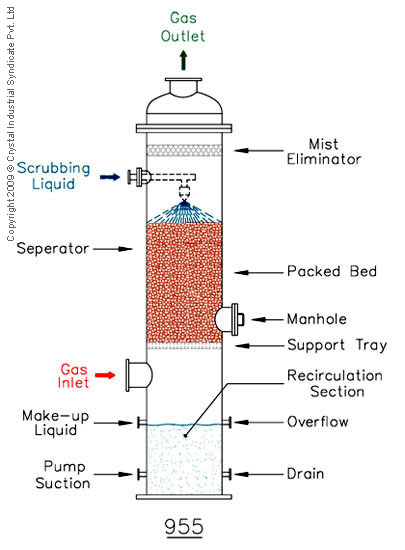

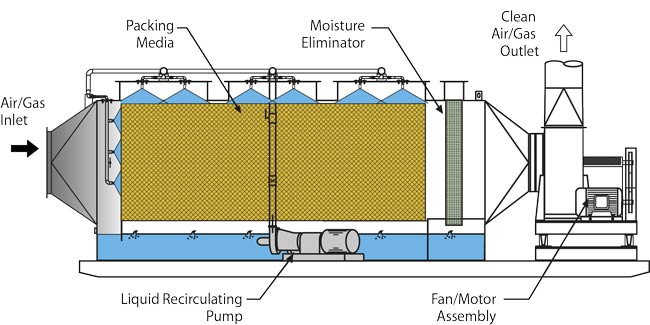

It is also hypothesized that the packing provides large interface area for the contact of liquid and gas phase inside the packed bed. They are designed for applications requiring high removal efficiencies of submicron particles between 05 and 50 micrometers in diameter4 A venturi scrubber employs a gradually. Typical nozzle scrubber efficiencies.

Liquid Scrubbing media Properties. Venturi Scrubber Design xls Scribd. Venturi scrubbers are generally applied for controlling particulate matter and sulfur dioxide.

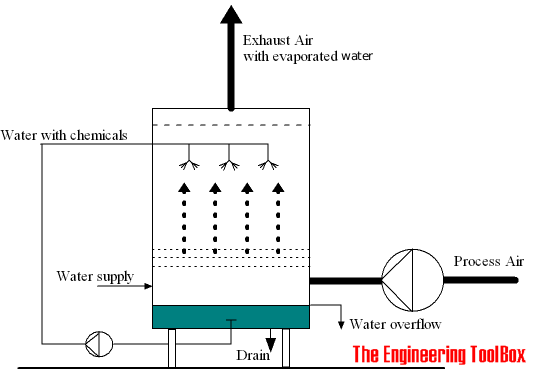

μ h scrubber humidifying efficiency t 1 initial dry bulb temperature o C t 2 final dry bulb temperature o C t w initial wet bulb temperature o C Scrubber Efficiencies. The rating mode allows you calculate the pressure drop and approach to flood for existing columns. Math Geometry Physics Force Fluid Mechanics Finance Loan Calculator.

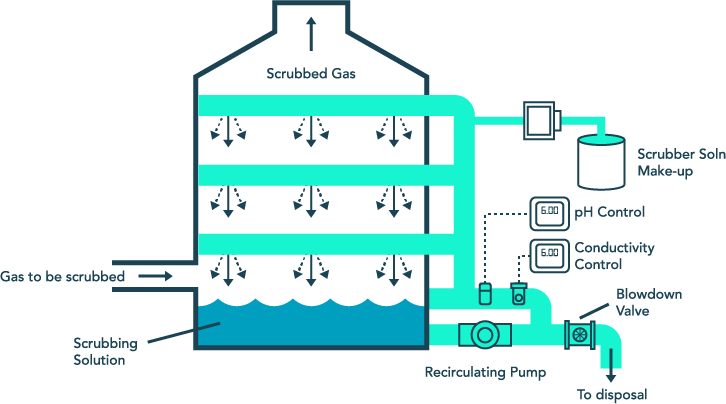

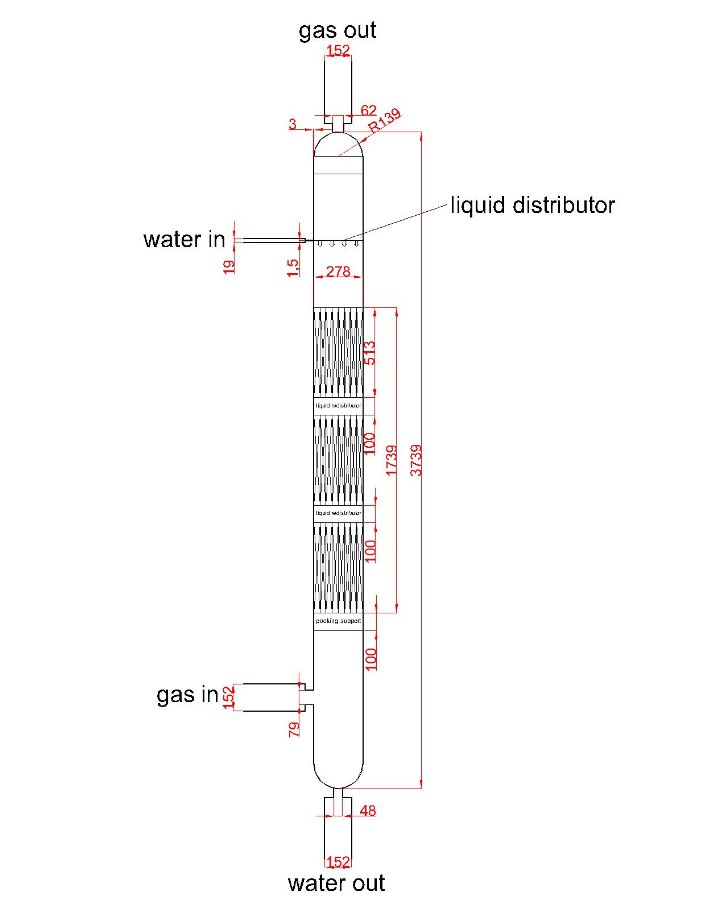

The design basis for new columns can be approach to flood maximum capacity or pressure drop. It is hypothesized that the packed bed scrubber design is dependent on the parameters like working pressure tower packing height and diameter of the packing bed. η collection efficiency of the venture scrubber fraction.

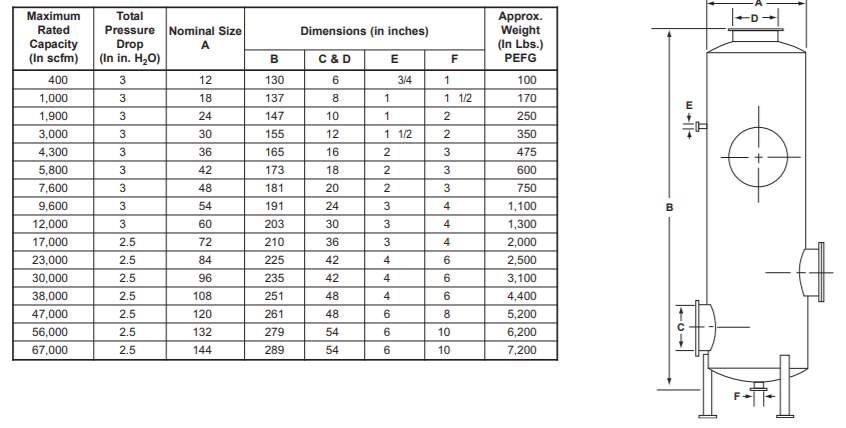

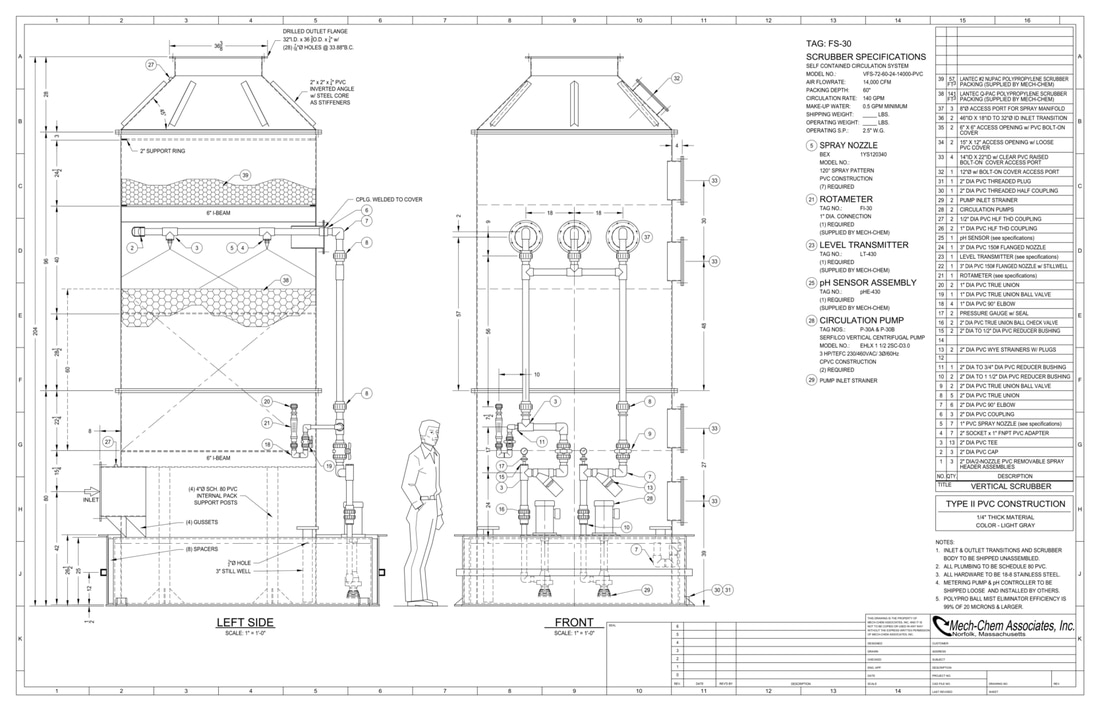

Just as fine particles in water colloids carry a charge of static electricity so do colloidal par-. Site Tri-Mer engineers determine the optimum tower diameter packing depth recirculation flow rate and mist eliminator requirement in microns. Liquid Density L 1100 kgm3 Conversion.

The scrubbing media used is water with 6 NaOH and the fluid to be scrubbed is a HC with a MW of 366 at 111 ºC and 1000 ppm of HCl. The PackCol program performs hydraulic design and rating calculations for packed columns and towers.

Liquid Density L 1100 kgm3 Conversion.

Site Tri-Mer engineers determine the optimum tower diameter packing depth recirculation flow rate and mist eliminator requirement in microns. η 1 e -kRsqrt ψ ---- 1 where. Spray tower scrubber design calculation xls. The safety valves discharge to the scrubber and the scrubber overhead vapor discharges to the flare system. The humidifying efficiency of the scrubber may be expressed as. The PackCol program performs hydraulic design and rating calculations for packed columns and towers. Just as fine particles in water colloids carry a charge of static electricity so do colloidal par-. Scrubbing media 20 NaOH. The optimum wet scrubber system has such design goals as maximum particulate collection low power consumption and low maintenance.

η collection efficiency of the venture scrubber fraction. The rating mode allows you calculate the pressure drop and approach to flood for existing columns. η collection efficiency of the venture scrubber fraction. Using the information gathered under the efficiency requirement section above and other factors specific to the. Considering 20 safety factor HETP 08450653m For separations requiring 15 to 25 theoritical stages a 15 design safety factor can be applied. BEST TO BE VIEWED IN 1080p. Liquid Viscosity µL 00035000 Nsm2 35 Cp 000350000 Nsm2.

Post a Comment for "Scrubber Design Calculation"